|

|

|

|

|

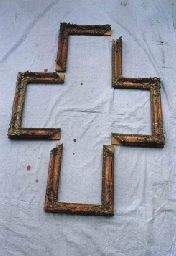

| Cross

Shape Frame in the Stile of Baroque, Beginning of 18th

Century

|

| Introduction |

|

|

Dimensions:

|

|

| 118cm

in height, 88cm in width, 7 cm on the thickest part |

|

| Final

facing: |

|

| Parcel

water silvered, parcel water gilded |

|

| Type

of treatment:

|

|

| Restoration |

|

| Storage

and display: |

|

| Memorial

museum collection |

|

|

|

|

|

|

|

Condition

The object

arrived in studio separated from the crown and side

elements. The body of the frame (fig.1.) was cowed with

thick layer of read and green pigment, oxidized bronze

powder emulsion, and embedded with surface dirt. The

crown and side elements (fig.2.) were also cowered with

oxidized bronze powder emulsion and embedded with surface

dirt.

Object was inoculated, and already damaged. The starting

places of inoculation were, fortunately, elements that

were used to hold crown and side elements (fig.3.),

made of pinewood and they were completely destroyed.

Inoculation progressed on the nearest parts of frame

and crown end side elements, causing minor damages,

except on the down side of the frame.

After small pressure applied on frame joints, they collapsed

(fig.4.). They were adhered with very thick layer of

bone glue.

Very delicate structure of crown and side elements was

cracked. Only two of four side elements were present.

Parts of ornaments on the all parts of object missed.

Technical

Analysis

Prior to

restoration work the following analysis were performed:

Analysis

of Materials and Techniques Involved

The body

of frame was made of Pinewood (Pinus nigra). Crown,

and side elements were made of Ashwood (Fraxinus sp.).

Frame ornaments wear made of Ashwood (Fraxinus sp.)

by wood-carving and then adhered on frame. Crown and

side elements were made by wood-carving too. All surfaces

were covered with traditional gesso approximately 2mm

thick, calcium carbonate powder and organic adhesive

probable Fish-eye glue), and then with layer of ocher

bole. Surface of frame was silvered and gilded by water

gilding technique. Silvered areas were burnished but

gilded ornaments were left non-burnished. Surfaces of

crown and side elements were gilded also by water gilding

technique. Some parts of ornaments were left non-burnished

too (fig.5. & fig.6.).

Identification

of Cowers on the All Parts of the Object

Surface

of frame was cowered with layer of pigment in form of

powder, mixed with inorganic binder. Side parts of frame

were cowered with layer of bronze powder mixed with

inorganic binder. Same bronze powder mixture was applied

on crown and side elements (fig1. & fig.2.).

|

|

|

|

|

|

|

|

|

|

|

|

|

|

fig.2.

click on to zoom |

|

|

|

|

|

|

|

|

|

|

fig.1.

click on to zoom |

|

|

|

|

|

|

|

|

|

fig.3.

click on to zoom |

|

|

|

| Choice

of Treatment

Treatment

on this object was performed in two phases:

Phase

I: Pest Elimination Procedure and Choice of

Cleaning Treatment

Pest

Elimination Procedure

Due to possibility

of active inoculation, fumigation procedure was applied.

Object was exposed to carbon de sulfide (CS2) for 12

ours.

Selection

of Solvents for Cower

Solvent

test was performed with admixture which was already

used in previous projects with very satisfying results.

It was the admixture of methylen chloride, methanol,

cellulose powder and paraffin oil. Evaporation time,

due to presence of cellulose and paraffin was appreciably

reduced, concentrating the reaction on cower. Admixture

was applied on samples taken from all parts of object

and after approximately 20 minutes of exposure, resulted

in complete dissolution of pigment cower substance and

bronze powder substance but only on the areas were surface

was burnished. On the areas where surface was not burnished,

dissolution of cower was partial. Thin part of cower

was strongly attached, on microscopically rough surface.

It was not possible to remove it by the help of solvent

due to fact that particles of bronze powder in that

case were not been attached on surface by means of inorganic

binder.

After scaning and zooming, it was determined that particles

of oxidized bronze powder were blended with particles

of gold and bole. Only possible way to remove it was

mechanical one but in that case, structure of object

would be endangered. Consequences of that procedure

would be only further damaging of object so it was decided

not to proceed with mechanical cleaning.

Cleaning

Process

Adopted

solvent was gradually applied and after 20 minutes dissolved

cower substance was rinsed with nitro-thinner (1). Object

was left for few ours to dray. Condition after cleaning:

fig.4. , fig.5. & fig.6..

|

|

|

|

|

|

|

|

|

|

|

fig.4.

click on to zoom |

|

fig.5.

click on to zoom |

|

fig.6.

click on to zoom

|

|

|

|

|

|

|

|

|

|

|

| Phase

II: Choice of Restoration Treatments

Selection

of the Materials and Procedures for Consolidation and

Recovering of Areas Damaged by Pests

Due to good

experience with admixture tested on all sorts of cracks

in past projects, it was tested for filling of areas

damaged by pests. Admixture was made of powdered gypsum

(CaSo4), kaolin and PVAC resin. Area was mechanically

cleaned of cutting dust and moistened with 15% ethyl

alcohol. Admixture was applied in few layers. Sample

was left to dray for 12 hours. Result was very firm,

consolidating backfill.

Selection

of the Materials and Procedures for Consolidation and

Recovering of Original Gesso

In order

to consolidate the cracks in original gesso, and make

solid ground for new gesso the 'contact ground' was

tested. Request was to obtain surface solid enough to

resist pressure during the burnishing of gold and silver

and porous to except new gesso. The ground was composed

of calcium carbonate, in form of fine powder - Bologna

chock, zinc oxide powder and PVAC resin. By the and

of mixing 90% Izo propil alcohol was added to improve

leaving of captured air. To make it applicable with

brush admixture was diluted with distilled water. Surface

was coated 3 times with time delay of 15 minutes to

provide solidification time for each layer. Sample was

left to dray for 12 hours. The result was solid but

porous surface, enough resistible on pressure preventing

the original gesso from delaminating.

Restoration

Process

Cracks in

crown and side ornaments were consolidated by inlaying

veneer peaces. Sides of cracks were mechanically flattened

and then peaces of veneer were inlayed and adhered with

aliphatic resin glue (2).

Veneer peaces and aliphatic resin glue (2) were also

used to fill gap between mortise and tenor in rejoining

process of frame structure. Gapes appeared after removing

thick layer of bone glue. Bone glue was melted with

beam of water steam and removed mechanically.

Some missing parts of ornaments were made by woodcarving

and the other by sculpturing.

Parts of wood carved ornaments including two whole missing

side elements were carved in ashwood (Fraxinus sp.).

Parts of wood-carved ornaments were adhered with aliphatic

resin glue (2) on appropriate places. They were supported

with thin dowels specially made for each of them (fig.7.).

Smaller parts of ornaments that missed were made by

sculpturing in Model plaster (3) with addition of PVAC

resin. Support for them was made of protected copper

streak.

Missing part of inside batten on the very frame was

made of model plaster and PVAC resin, with help of silicon

mold. First, thin plate (2mm) made of ashwood was affixed

and adhered with aliphatic resin glue on the place of

missing batten and then, ornament made in mold was adhered

on it. Ornament was very thin, about 2mm in order to

correspond, adhered on wooden plate, to other parts

of the batten (fig.8.).

For recovering of the damages caused by pest, tested

admixture was applied on all damaged places in corresponding

amount. Damaged places were mechanically cleaned of

cutting dust and moistened with 15% Ethyl alcohol. Admixture

was applied in few layers with moistened spatula, till

gaining of satisfying shape. After 12 hours areas of

intervention was better shaped with help of turbine.

|

|

|

|

|

|

|

|

|

fig.7.

click on to zoom |

|

fig.8.

click on to zoom |

|

|

|

|

Prior to

application of the 'contact ground' whole surface of

object was cleaned whit 96% etil alcohol. The 'contact

ground' was applied in three layers as it was tested

and then it was left to dray for 2 hours. New traditional

gesso consists of technical whiting (CaCo3), zinc whiting

(Zn2O) and rabbit skin glue was applied shortly afterwards

in four layers. Every layer was left to solidificate

for 15 minutes. The ground was applied on all surfaces.

The new gesso was not applied on surfaces of batten

and corner ornaments of very frame. Gesso was not necessary

to apply on them due to fact that they would not be

burnished and additional gesso would only urge change

of delicate shape of ornament.

After 12 ours all surfaces of object were shaped with

sandpaper. In order to prepare flat and smooth surface

important for quality of water gilding. Sanded surfaces

were colored with ocher bole and sanded again with 4

grades of sandpaper. During the sending surface was

rinsed with mineral spirit.Next

12 ours object was left to dray (fig.9., fig.10. &

fig.11.).

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

fig.10.

click on to zoom |

|

|

|

|

|

|

|

|

fig.9.

click on to zoom |

|

|

|

fig.11.

click on to zoom |

|

|

|

Bole

mixed with 5% rabbit skin glue was applied in 6 layers

and then gilding and silvering was performed by water

gilding technique. After 12 our gilded and silvered surfaces

were partially burnished.

Due to fact that this object will not be exposed to the

circumstances of everyday use, final protection was carried

out with prefabricated protection spray for luminous surfaces

(4) in order to prevent process of patination of silver.

Good feature of spray is anti static reaction so object

will be protected from dust accumulation (fig.12., fig.13.

& fig.14.).

Mounting

New elements

for mounting of the crown and side elements were made

of pinewood (Pinus nigra) and adhered oh the frame with

heat reactive synthetic glue (5). Crown and side elements

were placed on them and also adhered with heat reactive

synthetic glue (5). Reason for using heat reactive synthetic

glue was slightly curved profile of crown and side elements.

Feature of the glue is to accumulate between curve shape

areas and flat areas and to hold same characteristics

trough the time.

|

|

|

|

|

|

|

|

|

|

|

fig.12.

click on to zoom |

|

fig.13.

click on to zoom

|

|

fig.14.

click on to zoom |

|

|

|

| List

of Used Prefabricated Materials

1. Nitro thinner: HB Body , Grece

2. Aliphatic resin glue: Titebond wood glue , Franklin

International, USA

3. Model plaster: Krone Hiliges Gipswerk, Germany

4. Protection spray for luminous surfaces: Kurt Vogelsand

GmbH, Germany

5. Heat reactive synthetic glue: Crown GmbH, Germany

Applied

Gold, Silver and Metal Leafs

Gold leafs:

Orange Doppel Gold, 22 Karat, Noris, Germany

Silver leafs: Blattssilber Normal, Noris, Germany

|

|

|

|

|

|

|